BASIC DRIVESHAFT ALIGNMENT

Ideally, the transmission output shaft should point directly at the

differential pinion shaft. This causes the driveshaft to make a straight

path, reducing the amount the u-joints move (and wear).

However, because the ride height changes with differing loads, and because

the leaf spring suspension allows the pinion angle to change under engine

load, the driveline angles will not always be ideal. In other words, the

driveshaft alignment will be a "compromise."

Typically, the best compromise for driveline alignment in the S-10

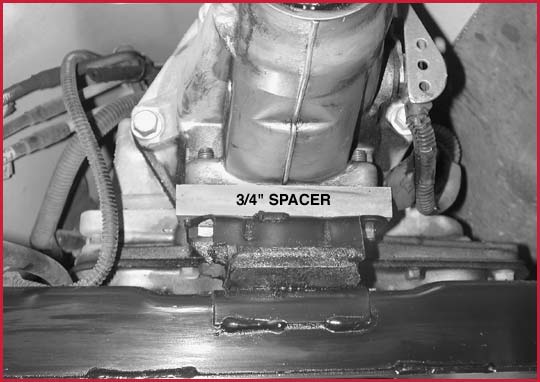

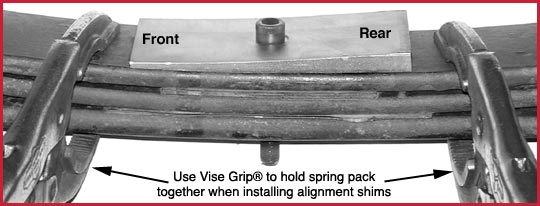

trucks and Blazers is to have the transmission output shaft point about 1" to 2" above the differential pinion shaft. This can be accomplished by installing adjustment shims between transmission, and the transmission mount. The reason to have it point slightly above the pinion shaft is so when the truck is carrying a load, the driveshaft angles will not get worse.

The pinion angle should be about 1/2° to 2° low when

the vehicle is parked on level ground. During normal driving, due to spring

wrap-up, the pinion angle will come up and be parallel to the transmission

output shaft.

S-10 short bed/short cab trucks lowered two-inches in the rear have

a driveshaft mis-alignment of:

- 1° to 2° between the transmission output shaft and the driveshaft.

- 1° to 2° between the driveshaft and the pinion shaft.

Mis-alignment beyond 3° causes noticeable vibration and excessive

wear on the u-joints.

One problem caused by vibration is that it will cause the truck to fall

apart quicker -- with the dash rattling, and interior parts coming loose.

The differential pinion seal and the transmission seal will also wear out and leak. The transmission tailhousing bushing will also wear out more quickly if the driveline is vibrating.

The driveshaft alignment kit will reduce the mis-alignments mentioned

above to less than 2° -- greatly reducing vibration and wear.

Advantages to improved driveline angles are:

- Reduced driveline vibration

- Less wear on driveline parts

- Better power transfer to the rear wheels

- Improved fuel mileage

|