|

S10 2WD Extended Cab

Driveshaft Alignment Kit

Stealth Conversions

The Parts Division of JTR (Jaguars That Run)

|

|

|

contact us |

|

|

| Home/Site Map | About JTR | Jaguar | Chevy

S-10 | Chevy

TPI & TBI | Astro

Van V8 | Volvo

200 | Volvo

700 | Datsun

Z Car |

|

Please Use the Books Ordering Form to

order manuals! |

|

|

back to S10 Parts Order Form

S10 2WD Ext. Cab Driveshaft Alignment Kit

for 4-cylinder, V6, and V8. |

|

S-10 2WD EXTENDED CAB DRIVESHAFT ALIGNMENT KIT |

|

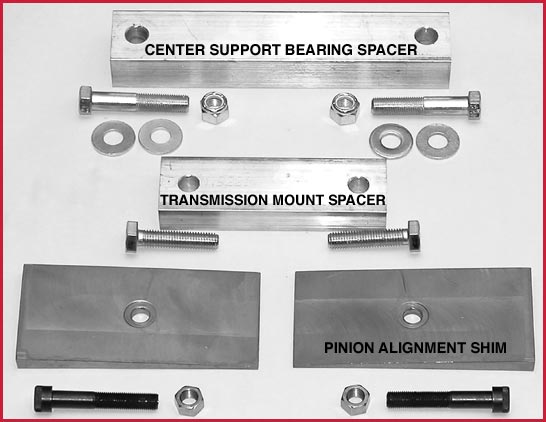

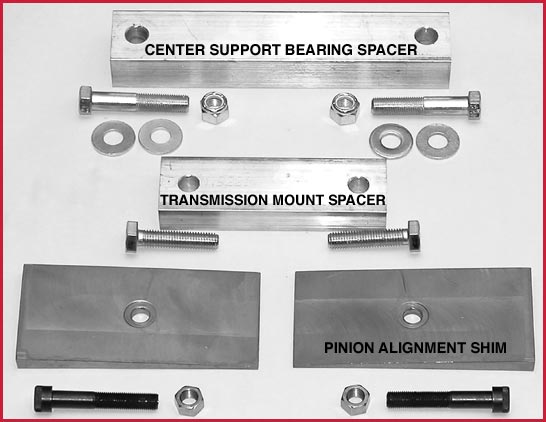

S10 2WD Extended Cab Driveshaft Alignment Kit. #S10-320, $45

Includes 3/4" thick billet aluminum transmission mount spacer

& longer mounting bolts; 1" thick billet aluminum

center-support bearing spacer & longer bolts; Billet pinion

alignment shims (also called axle alignment shims); and new mounting

bolts.

Specify 2° or 3° or 4°(2° for trucks with stock ride height, 3° pinion alignment

shims for trucks with the ZQ8 sport suspension or lowered 1–2 inches, and 4° for trucks lowered 3–4 inches.)

|

|

|

|

The 2WD Extended Cab Driveshaft Alignment Kit

Part # S10-320. Shipping weight, 6 lb

The kit includes:

- 3/4" thick aluminum transmission mount

spacer, and longer mounting bolts to raise the transmission 3/4"

- 1" thick aluminum center-support bearing

spacer, and longer bolts to raise the center support bearing 1"

- Solid luminum pinion alignment shims, and new mounting

bolts (specify 2° for trucks with stock ride height, and 3°

pinion alignment shims for lowered trucks and trucks with the ZQ8

sport suspension.)

Stock (4-cylinder and V6) S-10 extended cab trucks

have a mis-alignment of:

- 2° to 3° between the transmission

output shaft and the front driveshaft.

- 1° to 3° between the front

driveshaft and the rear driveshaft (depending on ride height)

- 4° to 7° between the rear

driveshaft and the pinion shaft (depending on ride height).

Mis-aligment

beyond 5° causes excessive wear on the rear u-joints.

The driveshaft aligment kit will reduce the mis-alignments

mentioned above to less than 2° — greatly reducing wear on

the double-cardan u-joint.

|

DOUBLE-CARDAN U-JOINT |

DOUBLE-CARDAN U-JOINT WEAR PROBLEMS AND REPAIR COSTS

Starting around 1995, the extended cab 2wd V6 trucks

with automatic transmissions came with the constant velocity “double-cardan”

style U-joints (shown above), to reduce driveline vibrations on extended

cab trucks.

The double-cardan U-joints have a high failure rate on

S-10 Trucks which have been lowered, or driven heavily loaded, due to

extremely bad driveline angles.

The extreme angles cause the grease to be thrown out of the cups that connect the two u-joints together, and this causes the center section of the joint to wear.

Driveshaft repair shops charge up to $300 to repair the

double-cardan U-joints -- and if corrective steps are not made, the joints

will fail again.

On a stock 2wd extended cab S-10, the mis-alignment between

the rear driveshaft and the differential pinion shaft is typically more

than 4°. On lowered or heavily loaded trucks. the mis-alignment can

exceed 9°.

On extended cab trucks which use conventional u-joints,

the poor driveshaft alignment can cause vibration problems. The extended

cab driveshaft alignment kit is recommended for all 2wd extended cab S-10

trucks.

Advantages to improved driveline angles are:

- Reduced driveline vibration

- Less wear on driveline parts

- Better power transfer to the rear wheels

- Improved fuel mileage (minimal)

|

TRANSMISSION OUTPUT SHAFT ALIGNMENT |

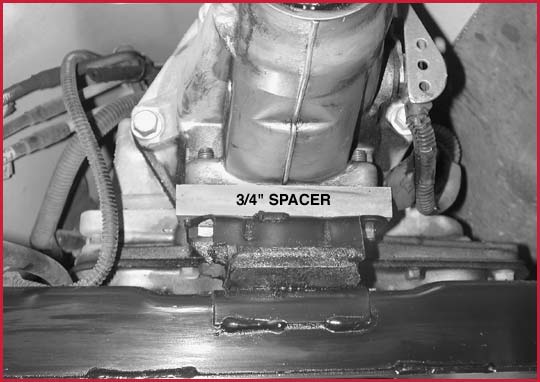

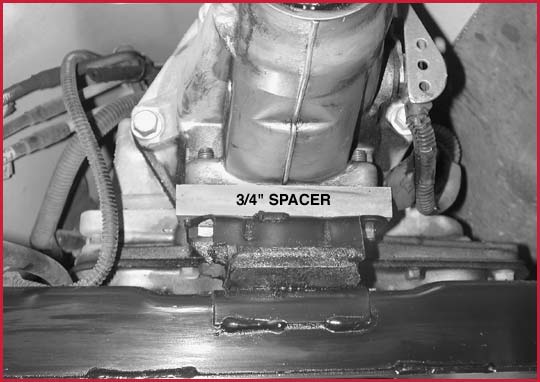

Transmission Output Shaft Alignment

The truck shown above is a 1998 Extended Cab with 4.3

V6 and automatic transmission. It has the ZQ8 Sport Suspension, which

lowers the truck about 2", compared to "normal" trucks.

For proper driveshaft alignment, the transmission output

shaft should point at the differential pinion shaft, when the truck is

at normal ride height.

To improve driveline angles, the transmission was raised

3/4" with an aluminum spacer. Ideally, the transmission should be

raised slightly higher, however, if the transmission were raised any higher,

the transmission would contact the floor of the truck and rattle on bumpy

roads, unless the floor of the truck is modified (hammered) to improve

clearance.

The bolts that attach the transmission mount to the transmission

are longer than stock to accommodate the thickness of the spacer, and

are included in the driveshaft alignment kit. |

CENTER SUPPORT BEARING ALIGNMENT |

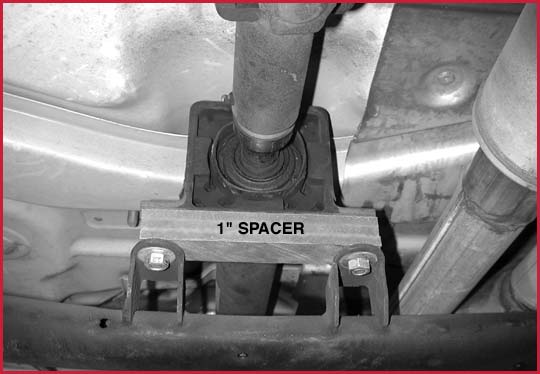

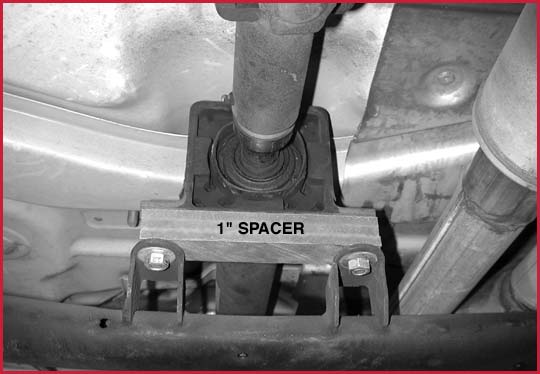

Center Support Bearing Alignment

For proper alignment, raising the rear of the transmission,

and raising the center support bearing is necessary on 2WD extended cab

trucks.

In the above photo, the center support bearing was raised

1" to improve driveline alignment. If the center support bearing

were raised any higher, the driveshaft would contact the floor of the

cab on bumpy roads.

The bolts that attach the center support bearing are

longer than stock to accommodate the thickness of the spacer, and are

included in the driveshaft alignment kit.

|

PINION ALIGNMENT SHIMS |

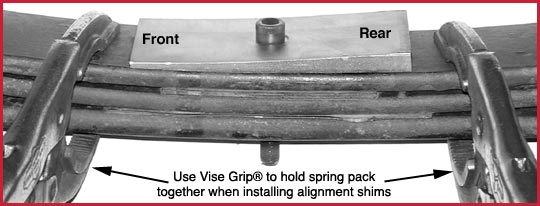

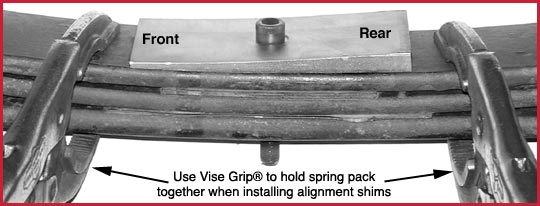

Pinion Alignment Shims

The Stealth Conversions pinion alignment shims should

be installed directly to the leaf spring with socket head cap screws supplied

with the alignment kit.

When installing the shim onto the leaf spring pack, hold

the spring pack together with a pair of Vise Grips® or C-clamps before

removing the original bolt.

If lowering blocks are used, the alignment shim should

be installed on top of the lowering block (see lowering block page). Stealth Conversions

Lowering blocks are designed to allow bolting alignment shims on top of

the lowering blocks.

|

Bolt Comparison |

Pinion Alignment Shim Installation Tips

The stock bolt (shown on top) that holds the leaf-spring

pack together is 3/8" diameter by 2" long with a 3/8"-24

thread. It has a head diameter of 9/16", and a head height of 5/16".

When installing axle alignment shims to adjust driveline

angles, the original bolt may be too corroded to remove without breaking

— or a longer bolt may be necessary.

The 2° and 3° axle alignment shims from Stealth

Conversions are about 1/4" thick at the center, and may require changing

the original leaf spring bolt with a longer bolt. The Stealth Conversions

Alignment shims come with a pair of 2-1/4" long socket head screws

and hex nuts.

If the socket head bolt is too long and interferes with

the lower shock plate, cut the bolt with a hack saw, or a grinder. |

Lowering Blocks and Pinion Alignment Shims |

Lowering Blocks and Pinion Alignment Shims

On trucks lowered with lowering blocks, we recommend billet

lowering blocks from Stealth Conversions.

The Stealth Conversions lowering blocks are unique in

that the top of the block is threaded. This allows the pinion alignment

shim to attach to the lowering block, while leaving the full height of

the cap screw for the rear-axle locating hole. |

|

|

| Home/Site Map | About JTR | Jaguar | Chevy

S-10 | Chevy

TPI & TBI | Astro

Van V8 | Volvo

200 | Volvo

700 | Datsun

Z Car |

Jump

Back to the Top

JTR engine swapping manuals are available directly from JTR Publishing,

As well as through a number of retailers, including:

• Summit Racing (S-10: Part #JTR-S10; Jaguar: Part #JTR-JAG),

• JEGS (S-10: Part #116549; TPI &

TBI: Part #117942),

• Steve Smith Autosports (S-10: Part #S212; TPI & TBI: Part #S195), and

• Classic Motorbooks (S-10: Part #116549; TPI & TBI: Part #117942;

Jaguar: Part #118438; Datsun Z: Part #115501; Volvo 200: Part #122587).

© JTR

All rights reserved. |

|